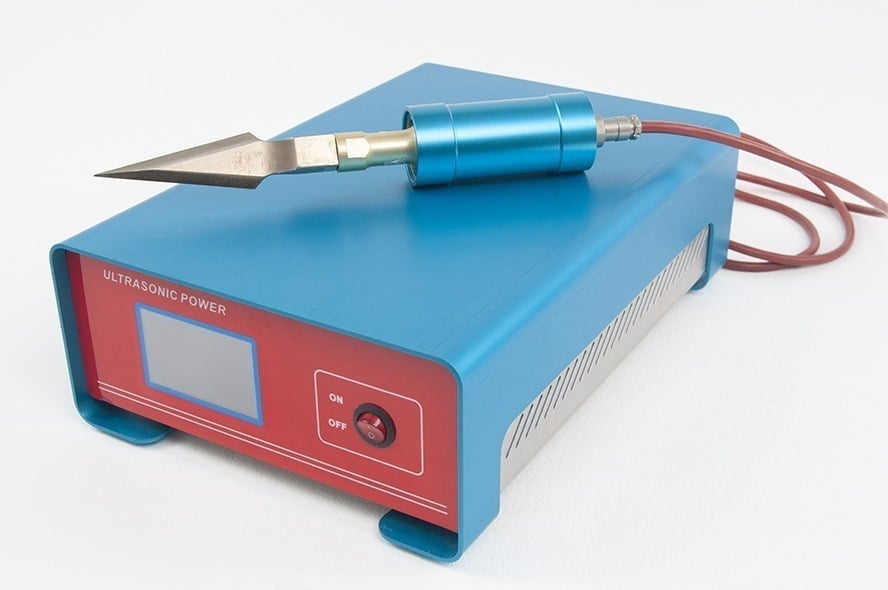

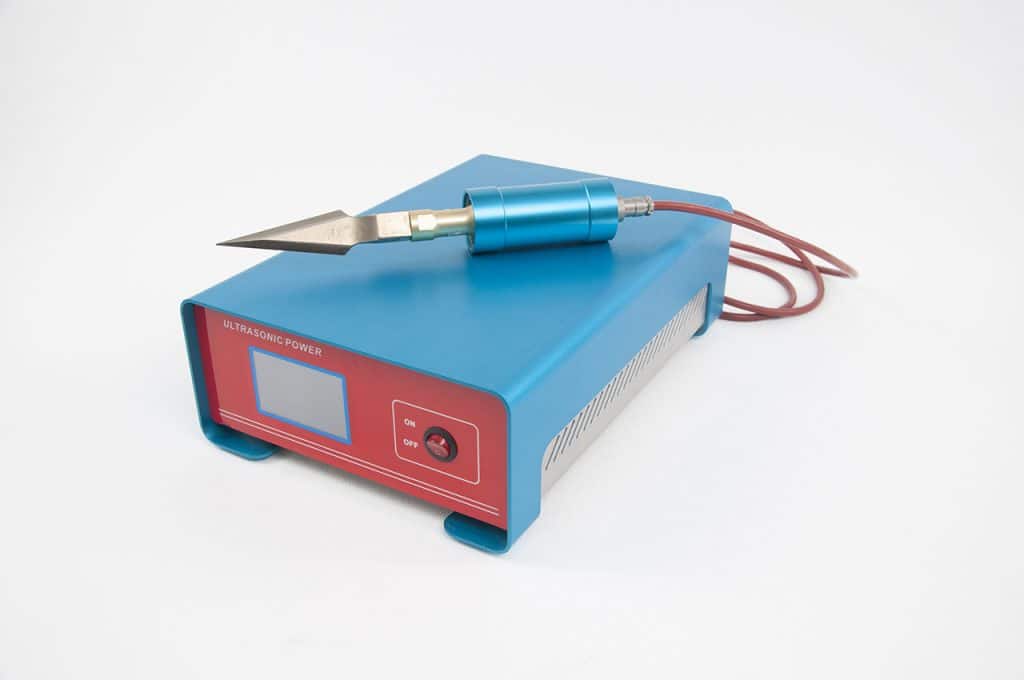

Sino Sonics Ultrasonic cutter system

These system is ideal for cutting rubber, plastic, food (cake, biscuits), composite aerospace materials such carbon fiber, Nomex and various honeycombs.

Cutter Process

Our ultrasonic cutting systems can be operated as hand-held units or incorporated into automated machinery. Our applications and design engineering team have developed industry leading tooling to meet the rugged demands of cutting applications. Solid, one-piece construction of horn blade technology virtually eliminates breakage and energy loss.

Cutter Design

Robust designs by us provide minimal blade flexure which yields straight cuts without having to support the blade.

Sinso Sonics cutting systems come in 20kHz, 25kHz, 30kHz, 35kHz, and 40 kHz frequencies. Where aggressive cuts are needed our 20 kHz ultrasonic generators and tooling are a great solution. If a smaller footprint or lighter payload is needed our 30 and 40 kHz cutting systems are a great fit and provide a quiet operating environment.

Sino ultrasonic horns designed to work with replaceable carbide cutting blades is a proven solution for aerospace materials that would otherwise not be feasible with standard ultrasonic tooling materials.

More info you can click aquí.

Standard Ultrasonic Cutting Blades & Knives

| Items | Details |

|---|---|

| Power in | 100 ~ 240v 50 ~ 60 Hz |

| Power output | 1200 Watt maximum ( 600 watt standard) |

| Power adjustment | 1% -100% | 1% progressive |

| Frequency | 25 khz /real-time display (19-26KHz sweep frequency automatic tracking) |

| Operating Mode | Programable, Pulse | Time | Continuous |

| User Program | 10 groups (Settable Storable Real-time View of Work Status) |

| Introducción en video | 4.7″ Touch screen |

| Low heat generation, Suitable for long-term continuous work. | |

| Blade sharper, Cutting speed faster. | |

| The cutting knife head can be polished. | |

| Cutting Blade | High speed steel (Hard steel), Replaceable blade. |

| Blade size, please contact our sales. | |

| Packing: | 1 Set ultrasonic generator 25k, 1200 watt. |

| 1 Pc cutter with mounted blade. | |

| 1 Pc power in plug & wire | |

| 3 Pcs fuse wire. | |

| 1 Pc connect cable for cutter ( 3 meter) |

| Items | Details |

|---|---|

| Power in | 100 ~ 240v 50 ~ 60 Hz |

| Power output | 1200 Watt maximum ( 600 watt standard) |

| Power adjustment | 1% -100% | 1% progressive |

| Frequency | 30 khz /real-time display |

| Operating Mode | Programable, Pulse | Time | Continuous |

| User Program | 10 groups (Settable Storable Real-time View of Work Status) |

| Introducción en video | 4.7″ Touch screen |

| Low heat generation, Suitable for long-term continuous work. | |

| Blade sharper, Cutting speed faster. | |

| 360° Rotation Orientation | |

| Cutting Blade | High speed steel (Hard steel), Replaceable blade. |

| Blade size, please contact our sales. | |

| Packing: | 1 Set ultrasonic generator 25k, 1200 watt. |

| 1 Pc cutter with mounted blade. | |

| 1 Pc power in plug & wire | |

| 3 Pcs fuse wire. | |

| 1 Pc connect cable for cutter ( 3 meter) |

Cutting Videos and more on youtube …

Ultrasonic cutting for plastic /fibreboard materials

Cutting & Sealing for Non-woven cloth

360° Rotation Orientation

Ultrasonic cutting for Plastic materials

Photo Gallery & Applications

Fibreboard/Plastic Cutting & Trimming

Fibreboard/Plastic Cutting & Trimming

Food/Cake/Biscuit Cutting

Rub/Plastic Cutting

Cloth /Film Cutting

Cloth /Film Cutting

Non-woven cloth industry

Packing

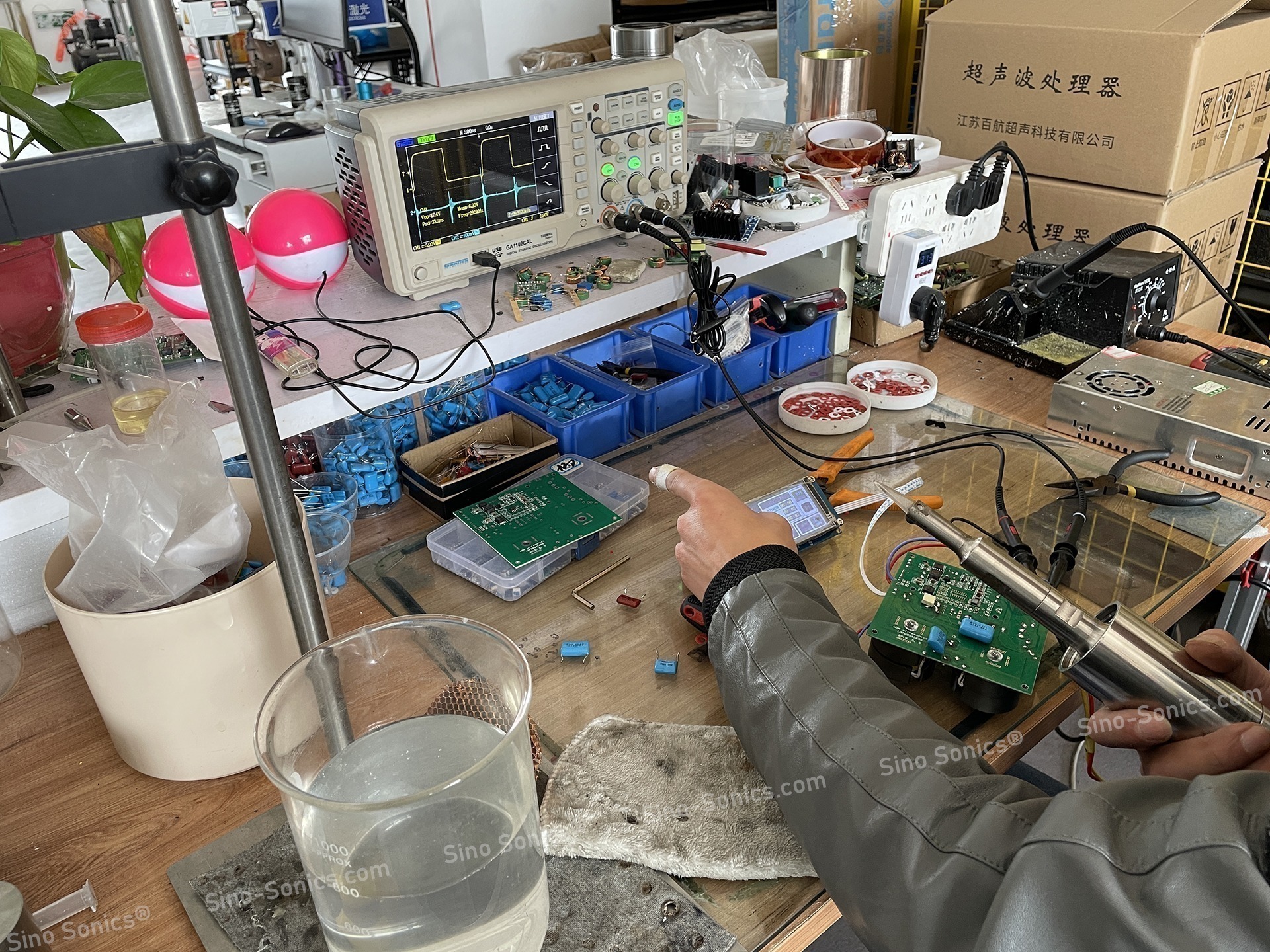

Testing blade & configuation

- Please contact our sales for more information.

Advantages

Clean

Ultrasonic Cuts are cleaner than conventional cutters with minimal debris

Ideal for cutting rubber, composite aerospace materials such carbon fiber, nomex,and various honeycombs

Replaceable

Replaceable blade technology reduces setup time and reduces replacement tooling costs.

Our ultrasonic horns designed to work with replaceable carbide cutting blades is a proven solution for aerospace materials that would otherwise not be feasible with standard ultrasonic tooling materials.

Frequencies

Available in 20,30, 35, and 40 kHz frequencies

Where aggressive cuts are needed our 20 kHz ultrasonic generators and tooling are a great solution. If a smaller footprint or lighter payload is needed our 30 and 40 kHz cutting systems are a great fit and provide a quiet operating environment.

Stock

Large inventory of standard carbide cutting blades for all shapes and sizes of applications.

Our applications and design engineering team have developed industry leading tooling to meet the rugged demands of cutting applications.

Design

Minimal blade flexure which yields straight cuts without having to support the blade