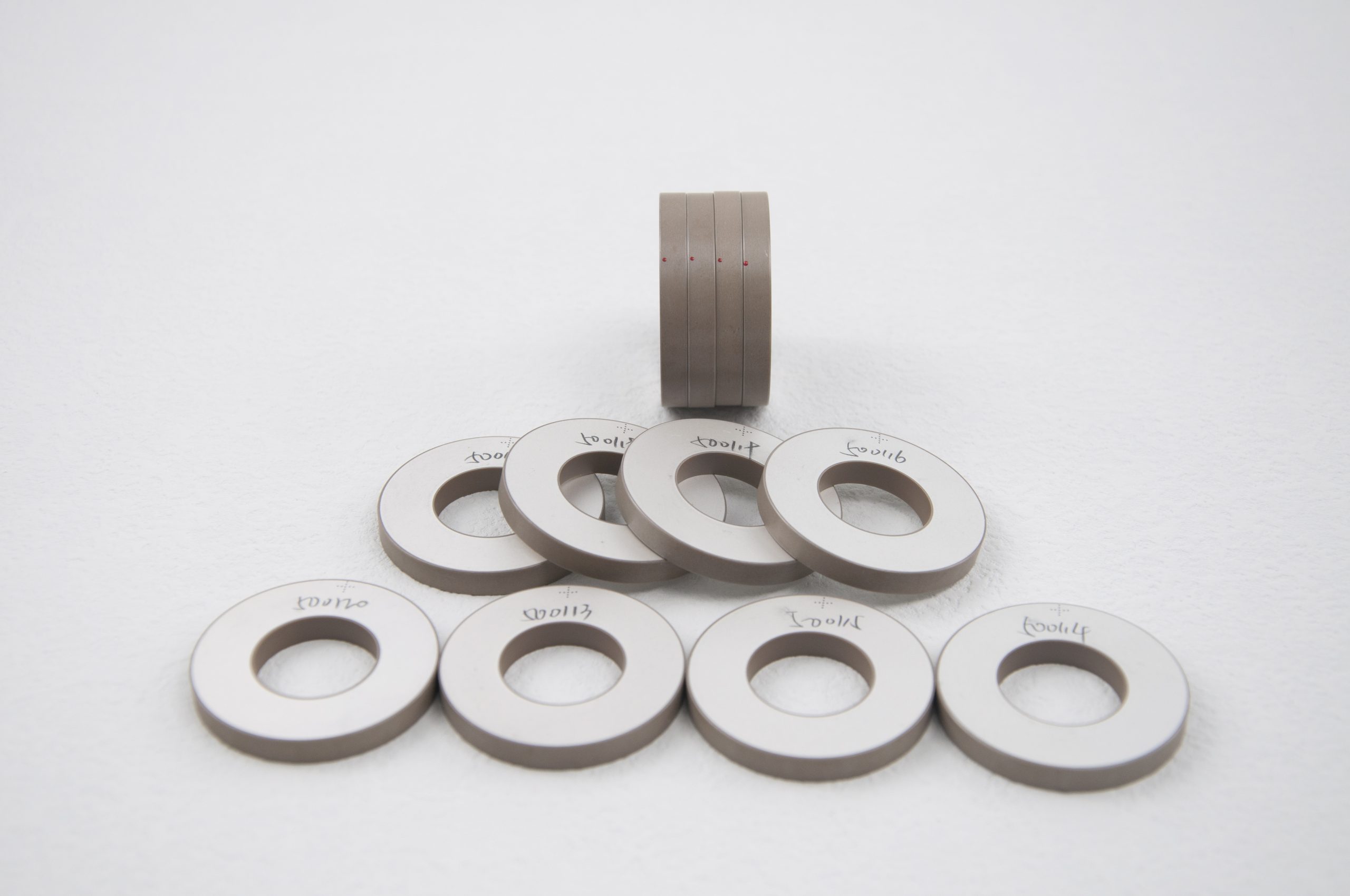

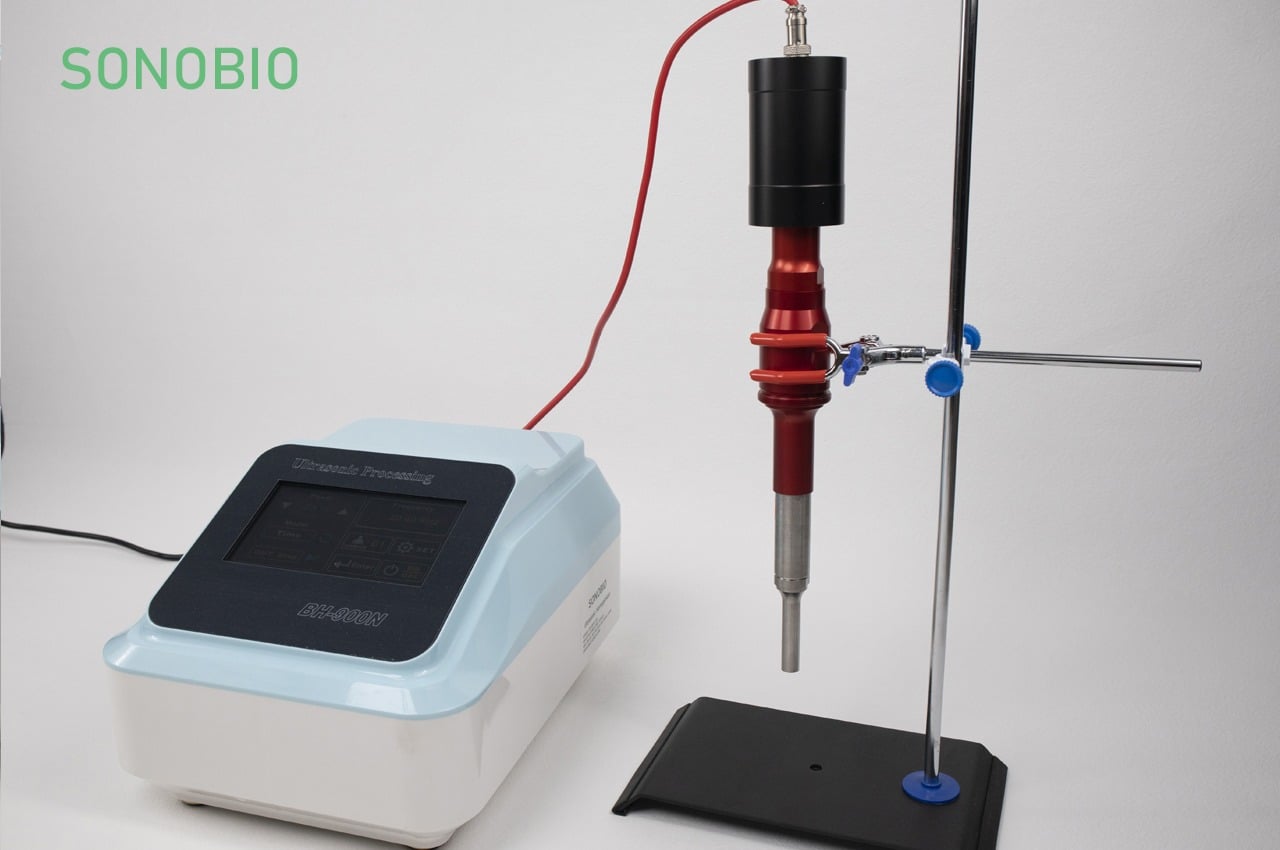

In the quest for excellence in piezoceramic materials for power ultrasonic transducers, the distinctions between PZT4 and PZT8 materials emerge as pivotal. Renowned for their application in high-power ultrasonic devices—ranging from welding and cutting to sonar systems—both PZT4 and PZT8 are hard piezoceramics distinguished by their intrinsic properties and application outcomes.

Understanding the Key Differences

The PZT8 variant, often favored for resonant devices, boasts a higher mechanical quality factor, Qm, attributing to its supremacy in stability under higher preloads and drive levels. Conversely, PZT4, though sometimes overlooked, holds significant advantages, including a higher output (d33) which translates to increased efficiency in energy transfer.

Diving into their specifics, PZT4 offers a relative permittivity (εr33) of 1650 compared to PZT8’s 1110, showcasing PZT4’s superior electrical energy storage capacity. The dissipation factor (tan δ) and electromechanical coupling (k33) further differentiate them, with PZT4 presenting higher values, indicative of its potential for greater energy conversion efficiency but with a caveat of increased dielectric loss.

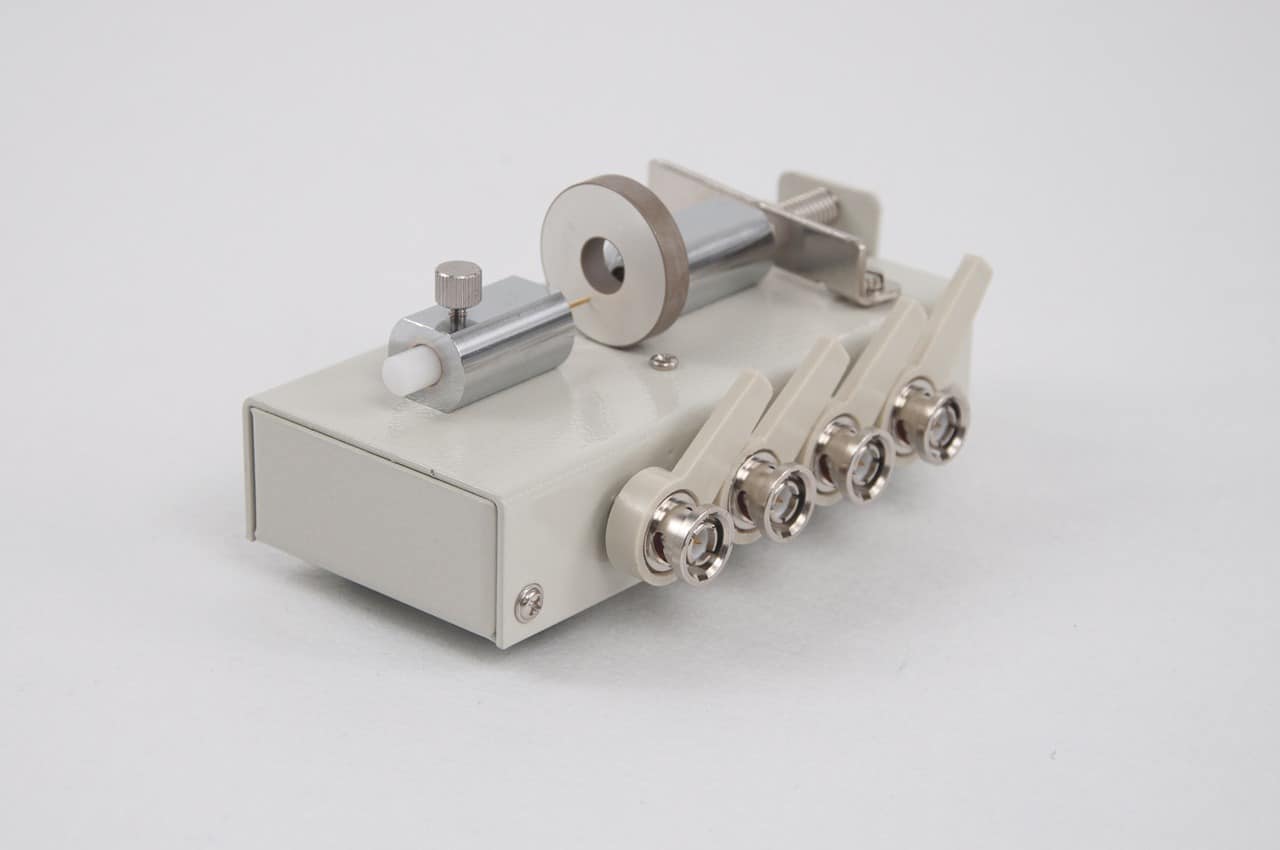

In practical ultrasonic transducer applications, these differences manifest in nuanced but critical ways. For instance, PZT4’s higher d33 value suggests an edge in output, making it a contender for scenarios where higher energy transfer efficiency is crucial. However, the perceived superiority of PZT8 in terms of Qm may not always hold, especially in Langevin bolted stack type transducers where mechanical joint losses dominate.

Sino Sonics’ Commitment to Quality

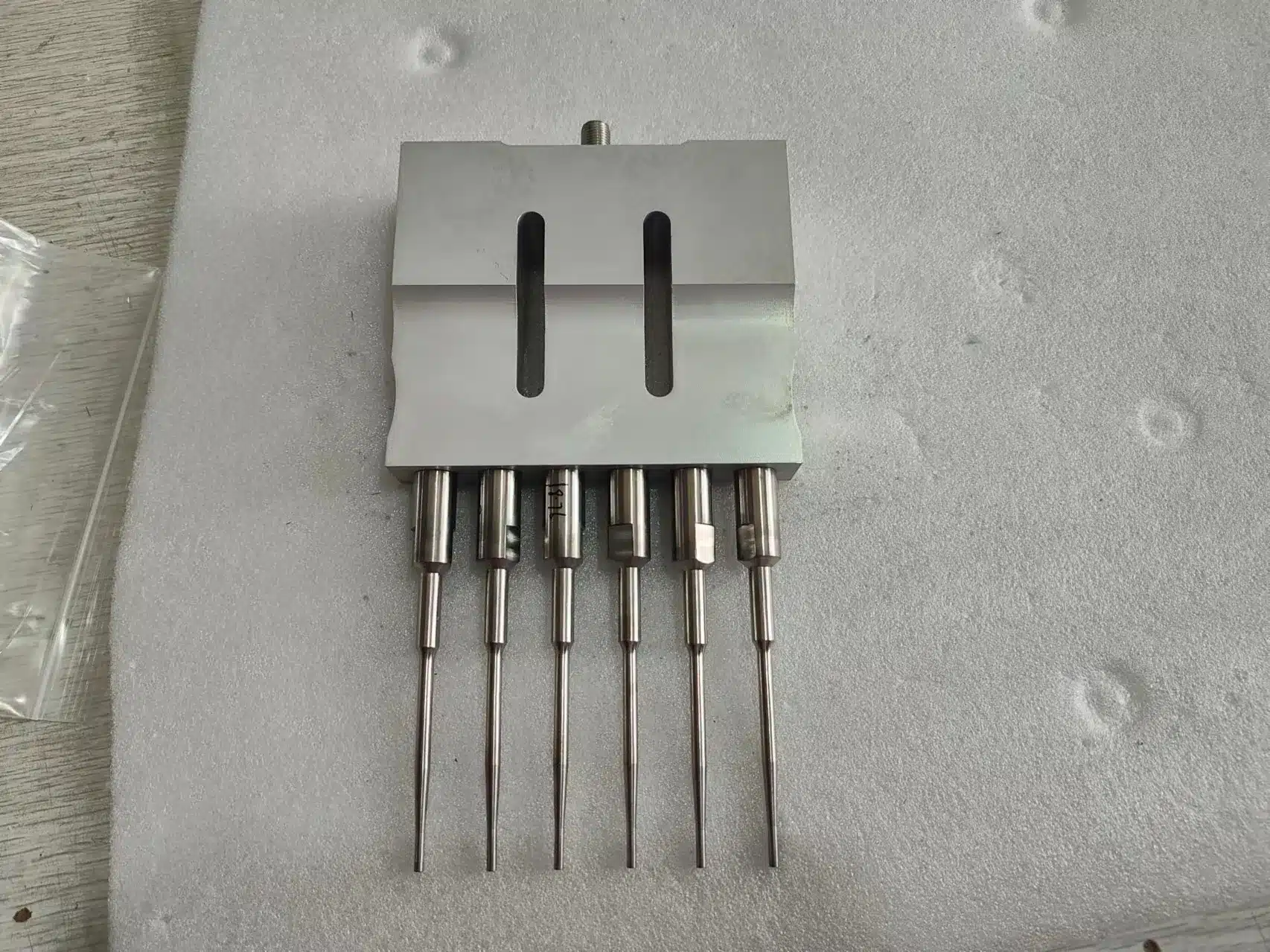

In the realm of piezo ceramic innovation, Sino Sonics stands at the forefront, offering a range of piezoceramic products tailored to meet diverse ultrasonic application needs. Recognizing the distinct characteristics and application advantages of both PZT4 and PZT8, Sino Sonics ensures that clients have access to materials that best match their specific requirements, guaranteeing optimal performance and reliability.

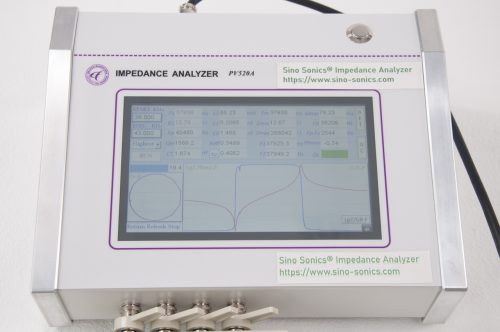

Data Visualization and Analysis

Analyzing the performance metrics of PZT4 and PZT8 reveals their unique profiles. For instance, the impedance and dielectric loss parameters provide insights into their operational efficiency and heat management capabilities, critical factors in high-performance ultrasonic transducers. Through comprehensive research, including Bode plots and thermal imaging, Sino Sonics elucidates the practical implications of these differences, aiding in informed material selection for ultrasonic transducer designers.

Conclusion: The Optimal Choice

Choosing between PZT4 and PZT8 hinges on the specific requirements of the ultrasonic application in question. With PZT4’s higher output and potential for increased energy efficiency, it offers significant advantages for certain applications. Conversely, PZT8’s stability and mechanical quality factor make it ideal for resonant devices where longevity and consistent performance under high stress are paramount.

In navigating these choices, Sino Sonics emerges as a trusted partner, providing not only the highest quality piezoceramic materials but also the expertise to guide clients towards the optimal material selection for their ultrasonic needs.