The application of ultrasonic in textile cutting is a groundbreaking advancement, offering unparalleled precision and efficiency. This method is particularly effective for complex materials and designs, transforming traditional cutting techniques.

Revolutionary Ultrasonic Cutting

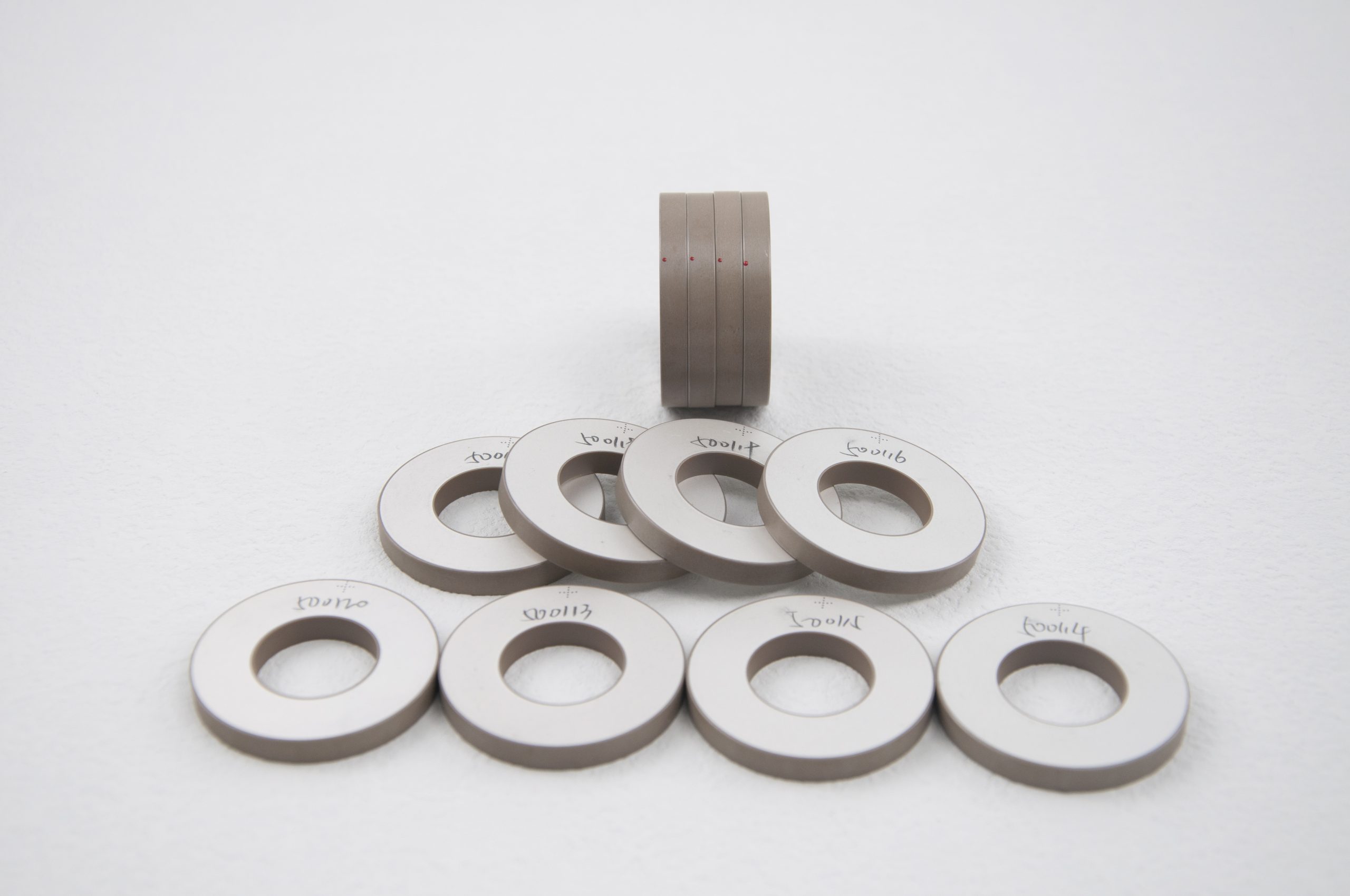

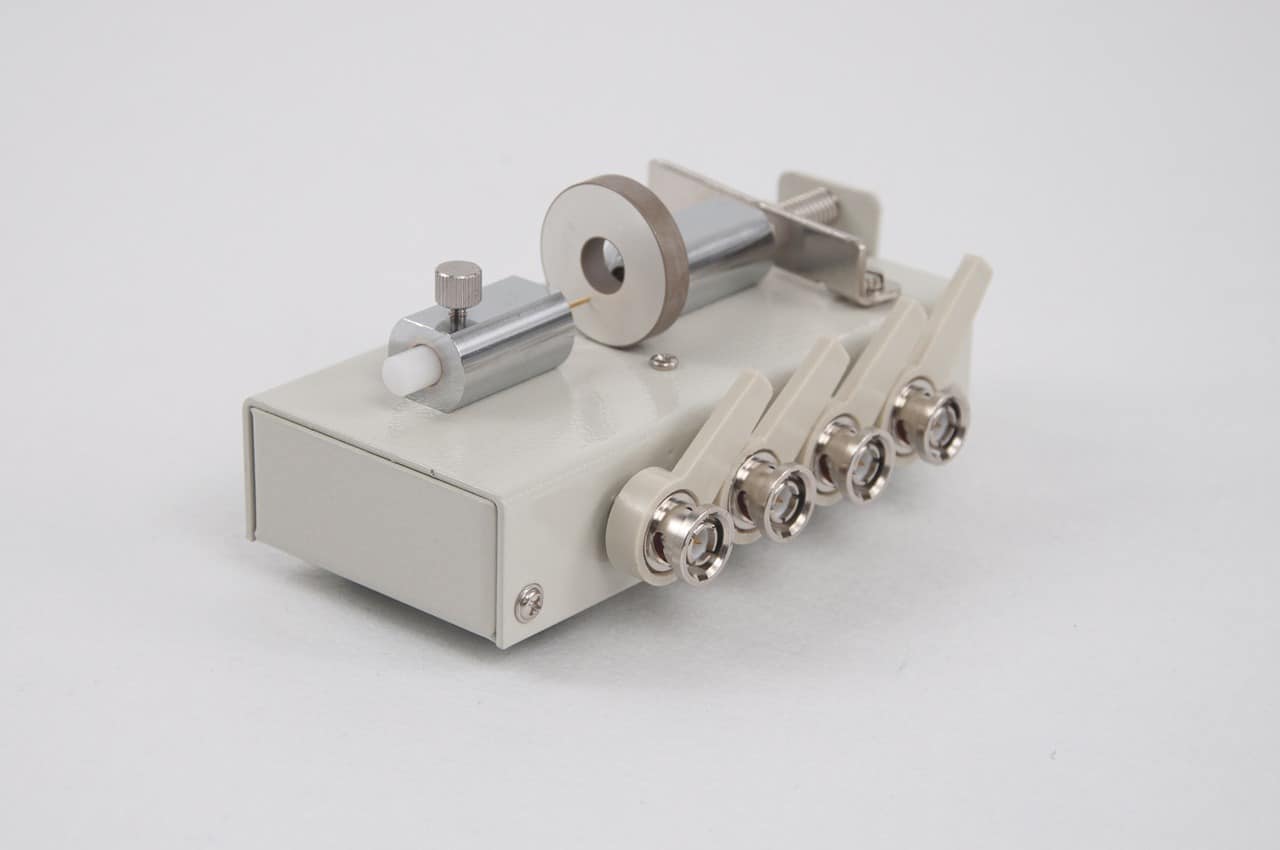

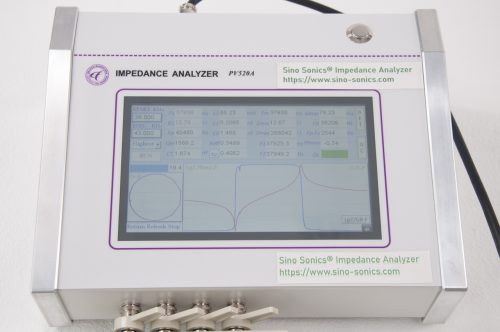

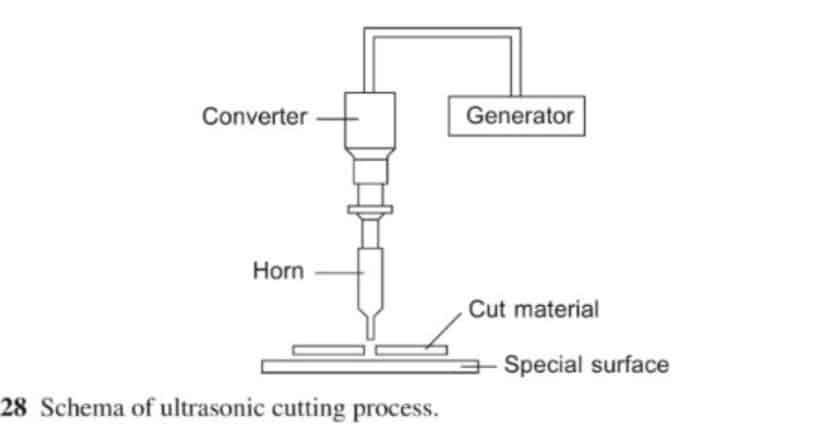

Ultrasonic cutting, diverging from conventional methods, utilizes high-frequency sound waves. These waves generate vibrations that strain the fibers of the material, facilitating a precise cut without direct contact. This approach is notably effective on challenging materials like Kevlar and cardboard, which are resistant to melting and thus difficult to cut using standard techniques.

Cold Cutting: An Innovative Edge

The ‘cold cutting’ technique of ultrasound is beneficial for materials that are sensitive to heat or moisture. Unlike traditional methods, it separates the material cleanly and accurately without removing any material. This results in precise, clean cuts and is an eco-friendlier option, significantly reducing dust and avoiding pollutants and fumes typically associated with other cutting methods.

Ultrasonic Cutting in Textile Manufacturing

In textile manufacturing, ultrasound cutting is essential for creating edges that are melted and sealed, preventing fraying. This method is particularly valuable for handling thick fabrics or fabrics with uneven weaves, where techniques like laser cutting might not be effective. Automated systems such as ‘Premiumcut ULS’ by Topcut Bullmer and ‘Elektron B2 Ultra’ by Aeronaut are designed to process materials straight from the roll or fixed ply, using either a conveyor system or a static table.

Precision and Versatility in Cutting

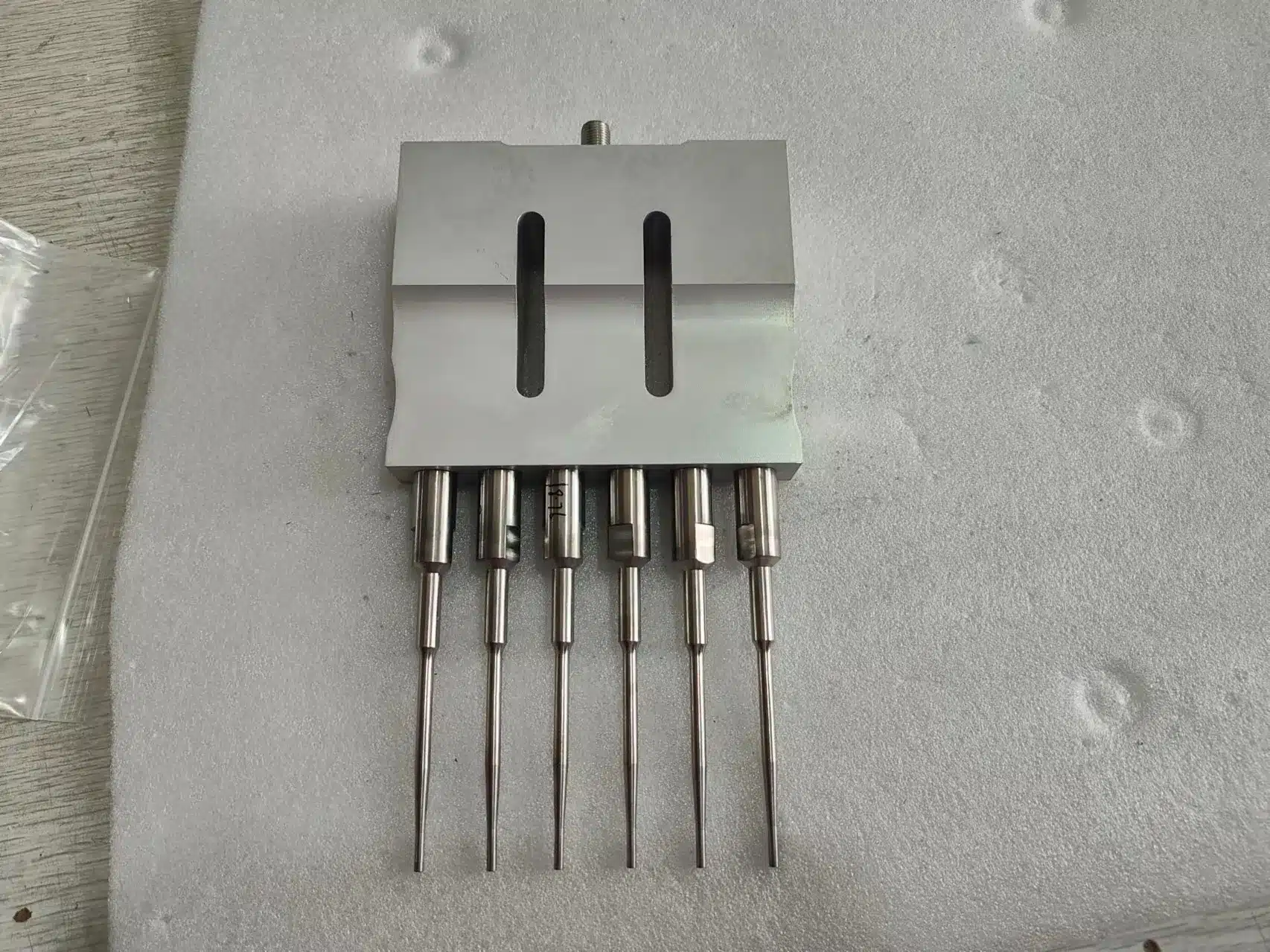

Ultrasonic cutters, resembling oscillating knives, are controlled by computer-operated heads, ensuring high precision in cutting various shapes and notches. This high level of accuracy is beneficial for both simple and complex designs, making ultrasonic cutting a versatile tool in textile manufacturing.

Conclusion

The integration of ultrasonic cutting in the textile industry signifies a progressive step towards more efficient, precise, and environmentally friendly manufacturing processes. Its ability to adapt to various materials and shapes makes it an indispensable tool, propelling the textile industry into a new era of technological advancement.

More info you can refer to Wiki