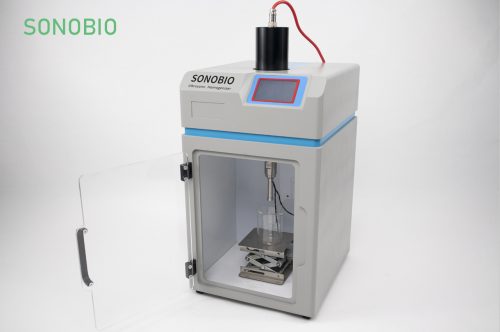

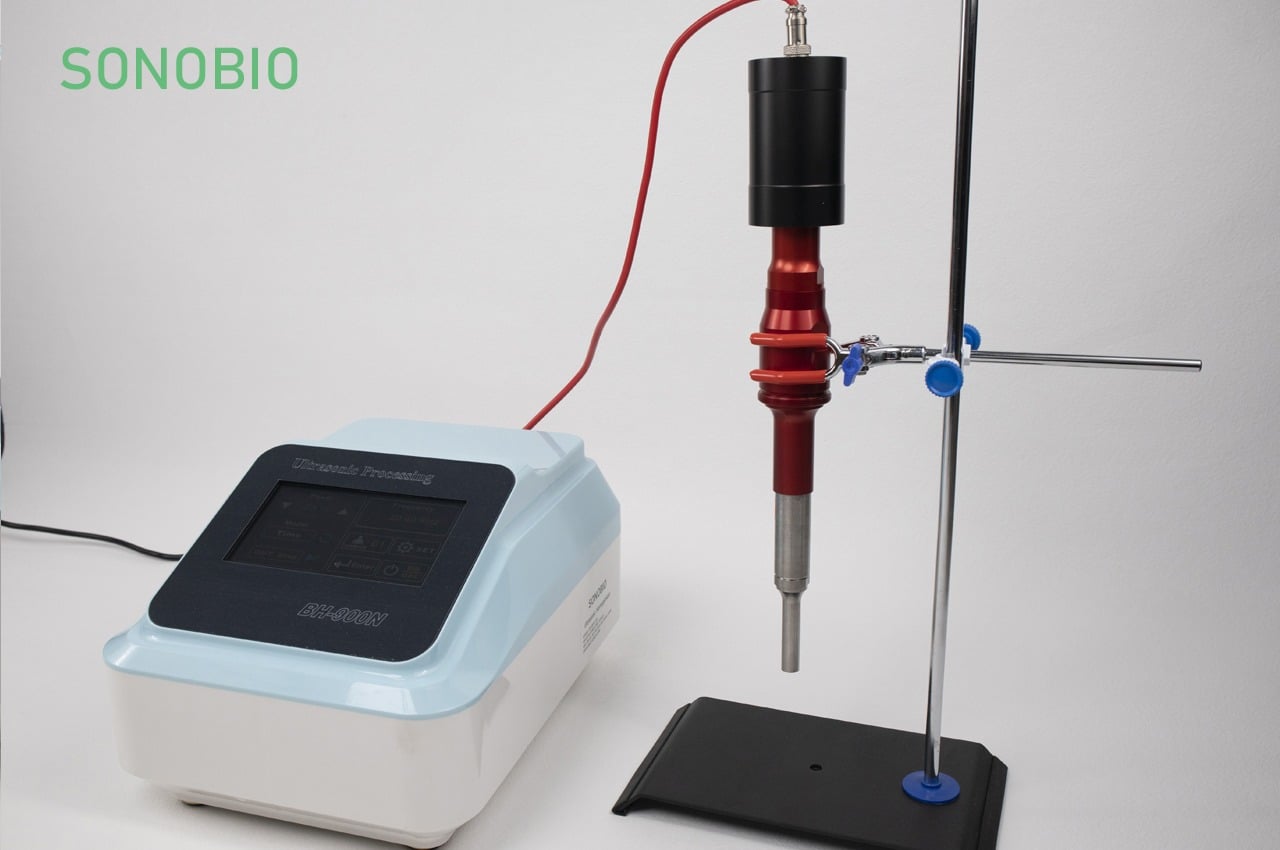

An ultrasonic homogenizer serves as a pivotal laboratory instrument designed to disperse, mix homogeneously, and process various types of samples. Employing ultrasonic technology, this equipment generates high-frequency sound waves transmitted into liquids, creating intense oscillations and powerful shear forces that effectively homogenize and disperse samples. Such devices find widespread application in scientific research, pharmaceuticals, the food industry, biotechnology, and various other fields, efficiently handling diverse sample types.

Key Components

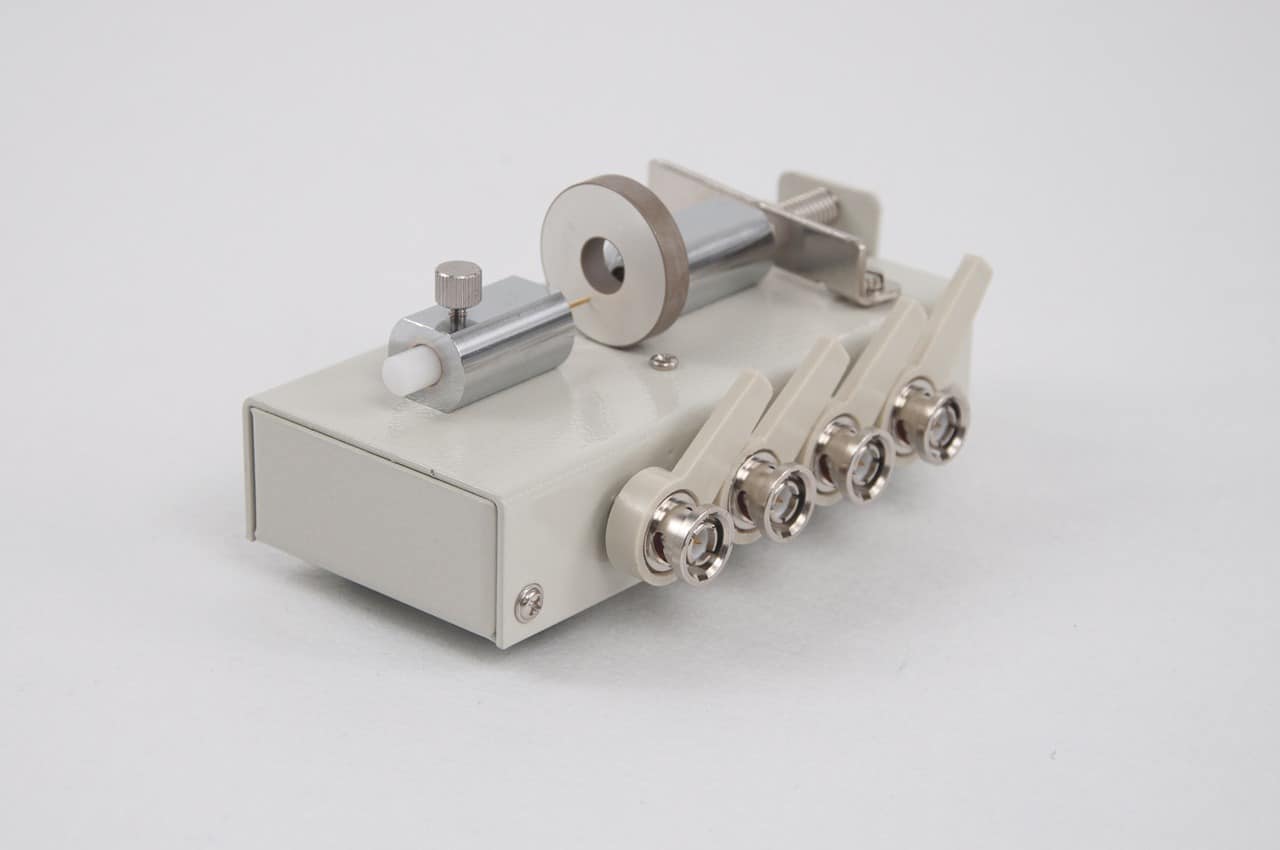

Ultrasonic Oscillator: At the heart of the ultrasonic homogenizer lies the ultrasonic oscillator, generating high-frequency ultrasonic fluctuations, typically above 20 kHz and sometimes surpassing 100 kHz. These fluctuations are conveyed to the sample through the oscillator’s transducer.

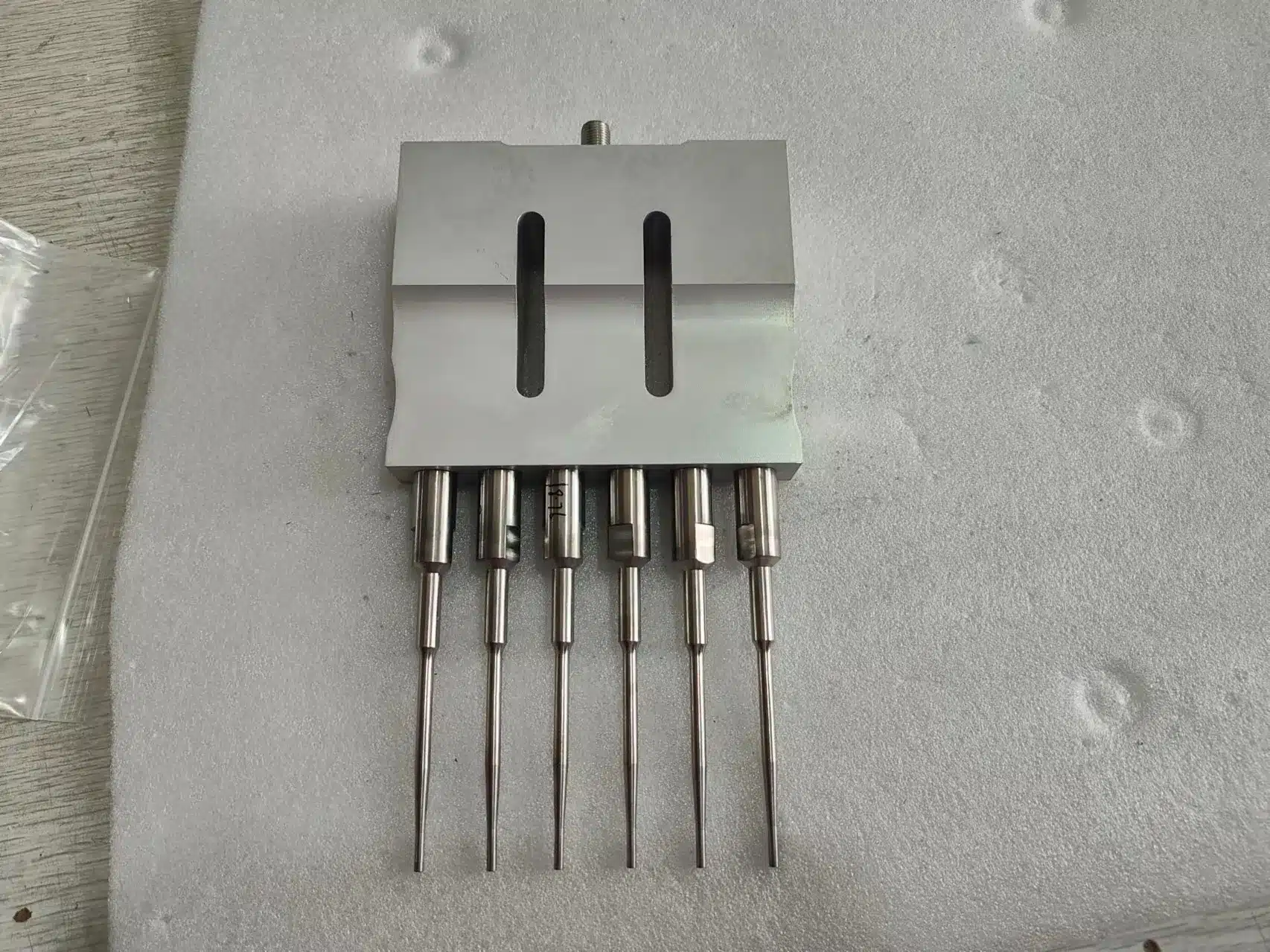

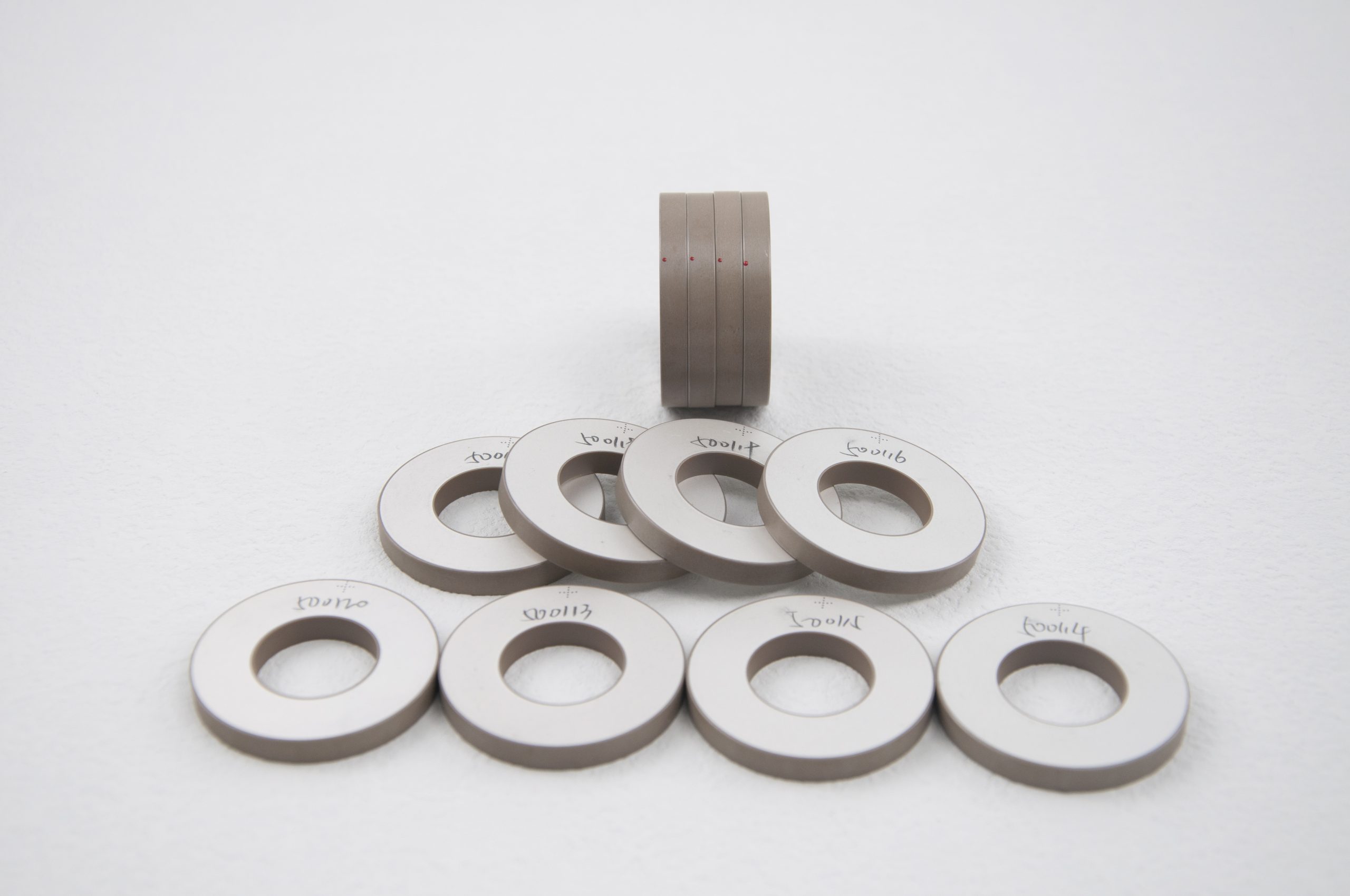

Transducer: The transducer within the ultrasonic oscillator converts electrical energy into acoustic energy, transmitting sound waves into the sample. Usually constructed from a metal oscillator, it effectively transmits sound waves into liquid or solid samples.

Processing Chamber: This chamber accommodates the sample. Often composed of stainless steel or glass to prevent chemical reactions with the ultrasound, it ensures the sample’s integrity during processing.

Workflow

Sample Preparation: The sample requiring homogenization or treatment is placed within the ultrasonic homogenizer’s processing chamber. This sample can be in the form of a liquid, suspension, emulsion, suspended solid, or powder.

Ultrasonic Application: Activating a high-performance ultrasonic homogenizer delivers high-frequency sound waves to the sample. These acoustic fluctuations induce intense mechanical shear and eddy currents, breaking up aggregates and dispersing particles uniformly, eliminating inconsistencies and aggregations in the sample.

Control Parameters: Operators regulate ultrasonic homogenizer parameters such as ultrasonic power, processing time, and temperature to meet specific sample processing needs.

Homogenization Completion: Upon completion of the processing, the sample is uniformly dispersed within the ultrasonic homogenizer, reducing particle size and dissolving it in the liquid, thereby increasing surface area and solubility.

Key Benefits

Highly Efficient Homogenization: Ultrasonic waves efficiently homogenize and disperse samples in a short time, saving on time and labor costs.

Non-thermal Process: Unlike several traditional homogenization methods, ultrasonic homogenizers typically maintain a non-thermal process, avoiding significant increases in sample temperature, beneficial for preserving heat-sensitive substances.

Wide Range of Applications: These homogenizers accommodate various sample types, including liquids, solid suspensions, and gases.

Environmentally Friendly: The usage of harmful chemicals is typically unnecessary with ultrasonic homogenizers, reducing environmental impact.

Common Application Areas

Pharmaceutical Industry: Utilized for drug preparation, nano-drug carriers, emulsions, and vaccine production.

Food Industry: For the preparation of emulsions, dressings, jams, sauces, and beverages, enhancing taste and texture.

Biotechnology: Essential for cell fragmentation, DNA and RNA extraction, protein purification, and particle dispersion.

Environmental Science: Applied in water sample preparation and particulate matter dispersion.

Material Science: Crucial in nanoparticle preparation and nanomaterials research.

If you want to know more details, click here, if you want to buy, click here.