Definition:

An ultrasonic cutter is a specialized tool that employs high-frequency ultrasonic vibrations to cut, trim, or shape various materials. It is a versatile and precise cutting device that finds applications in a wide range of industries, including manufacturing, textiles, food processing, and more. The fundamental principle behind an ultrasonic cutter is the conversion of electrical energy into mechanical vibrations, resulting in clean and efficient material cutting.

Applications:

Ultrasonic cutters are extensively used in the following industries:

- Textiles: In the textile industry, ultrasonic cutters are employed for precise and clean cutting of fabrics, including woven and non-woven materials. They are particularly valuable for textiles due to their ability to create clean edges without fraying.

- Food Processing: Ultrasonic knives are used to cut various food products, such as cakes, cheeses, and confectionery. The pressure-free cutting ensures that delicate food items maintain their shape and integrity.

- Manufacturing: Ultrasonic cutters are applied in manufacturing processes to cut and shape a wide array of materials, including plastics, rubber, composite materials, and more. They excel in applications that require precision and efficiency.

Types:

Ultrasonic cutters come in various types to cater to specific industry needs. Some common types include:

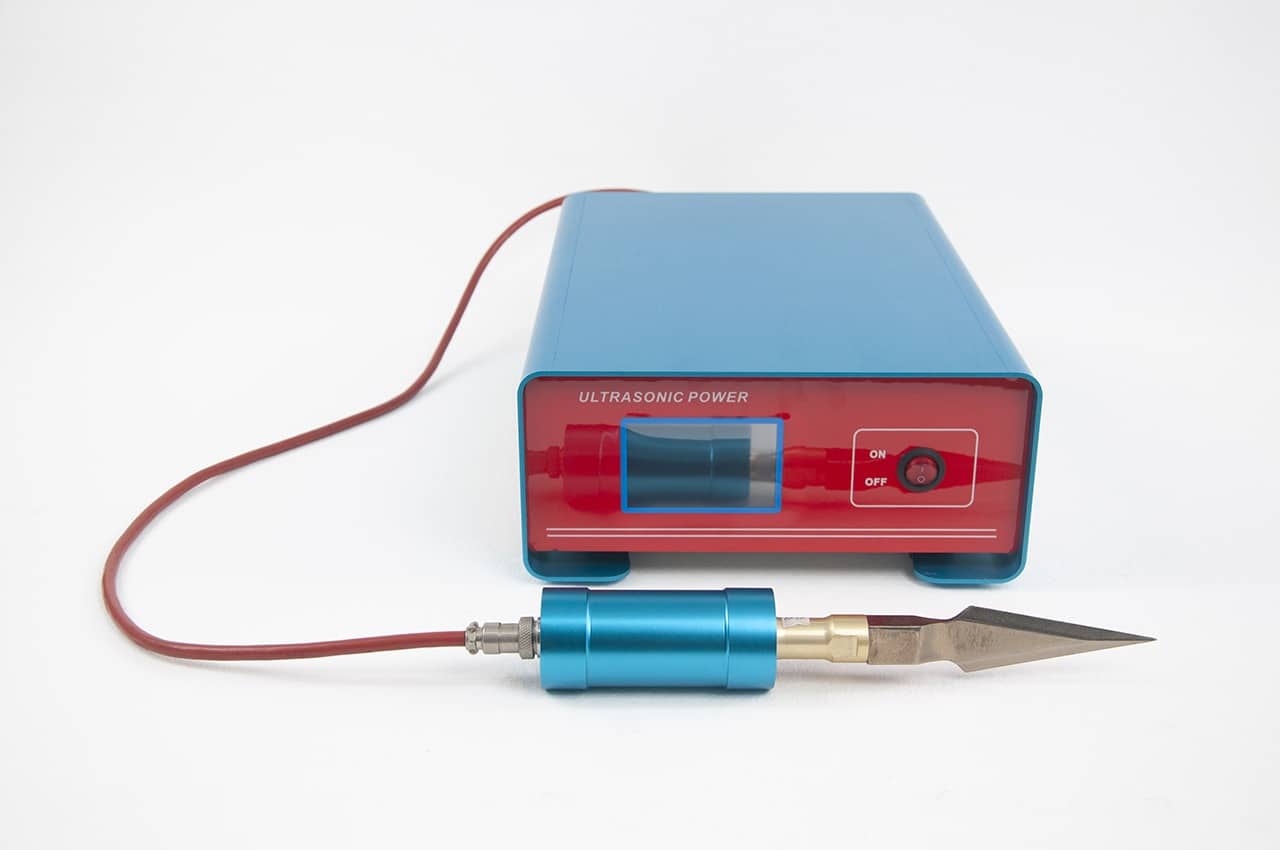

- Handheld Ultrasonic Cutters: These portable units are manually operated and are used for intricate or smaller-scale cutting tasks. They offer flexibility and ease of use.

- Automated Systems: These systems are integrated into production lines and machinery, allowing for high-throughput and automated cutting in industrial settings. They are ideal for mass production.

- Ultrasonic Welding and Cutting Systems: Some ultrasonic cutters are combined with welding capabilities, enabling the simultaneous cutting and sealing of materials, making them suitable for applications like packaging.

Working Principle:

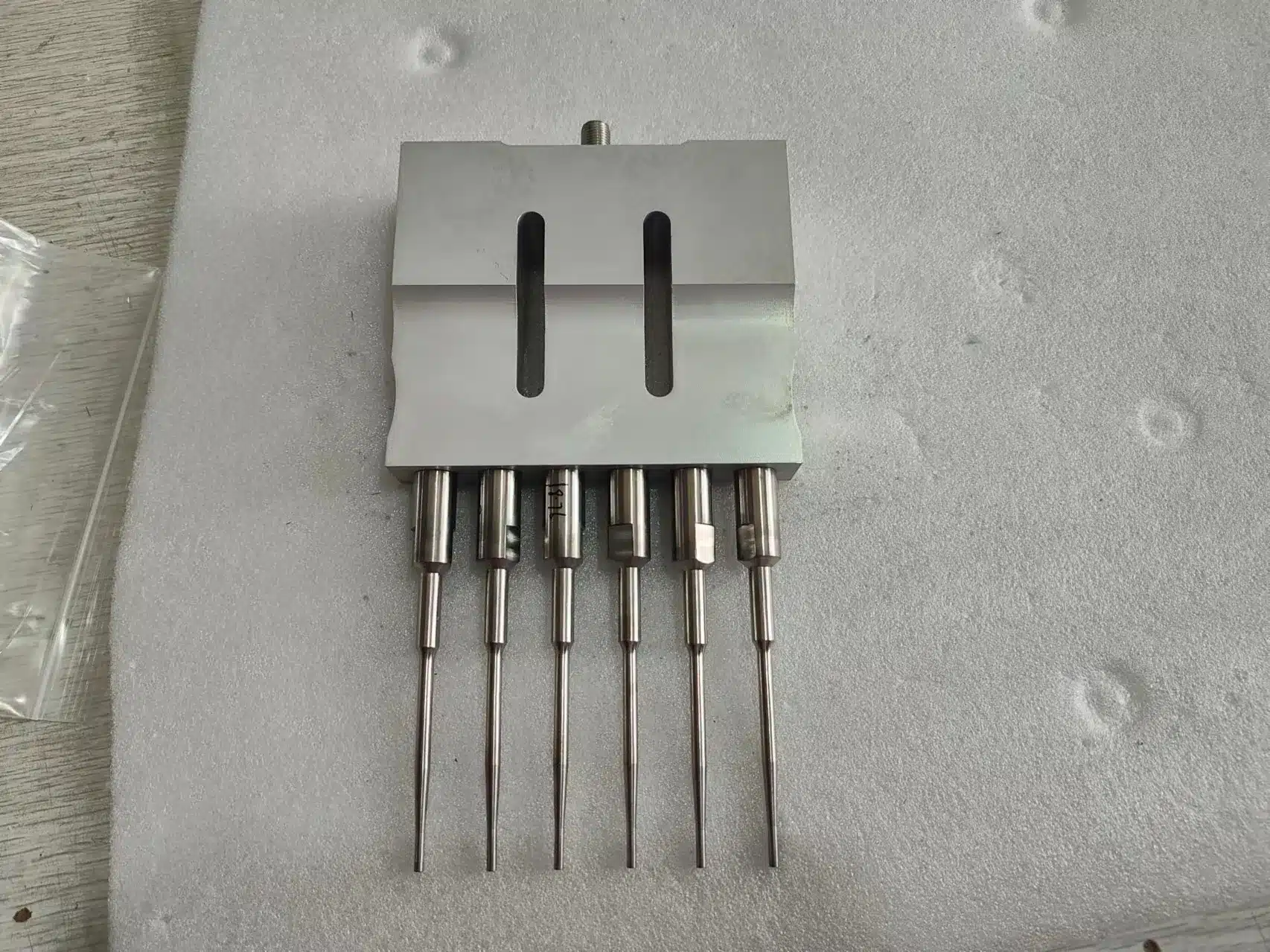

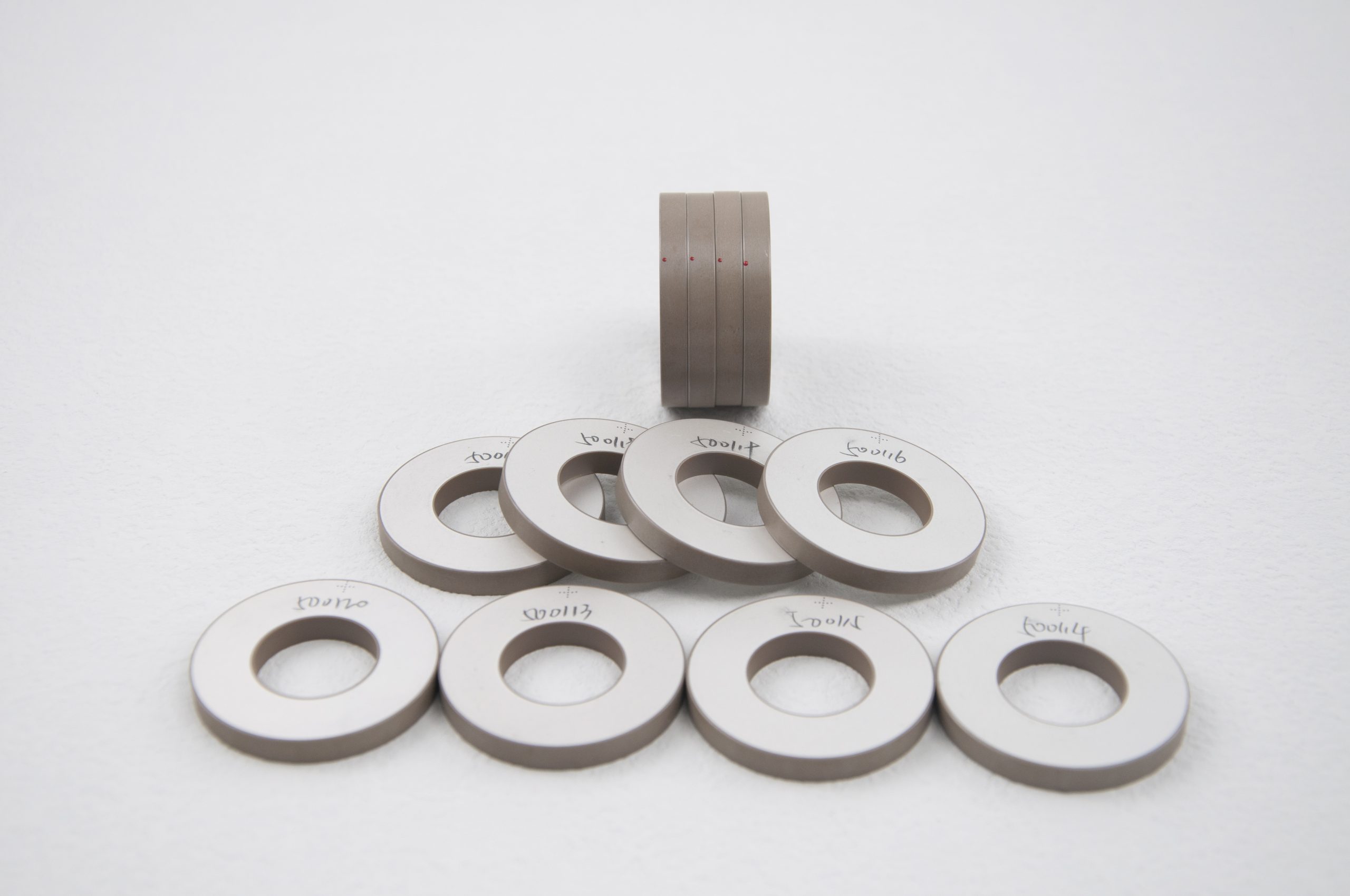

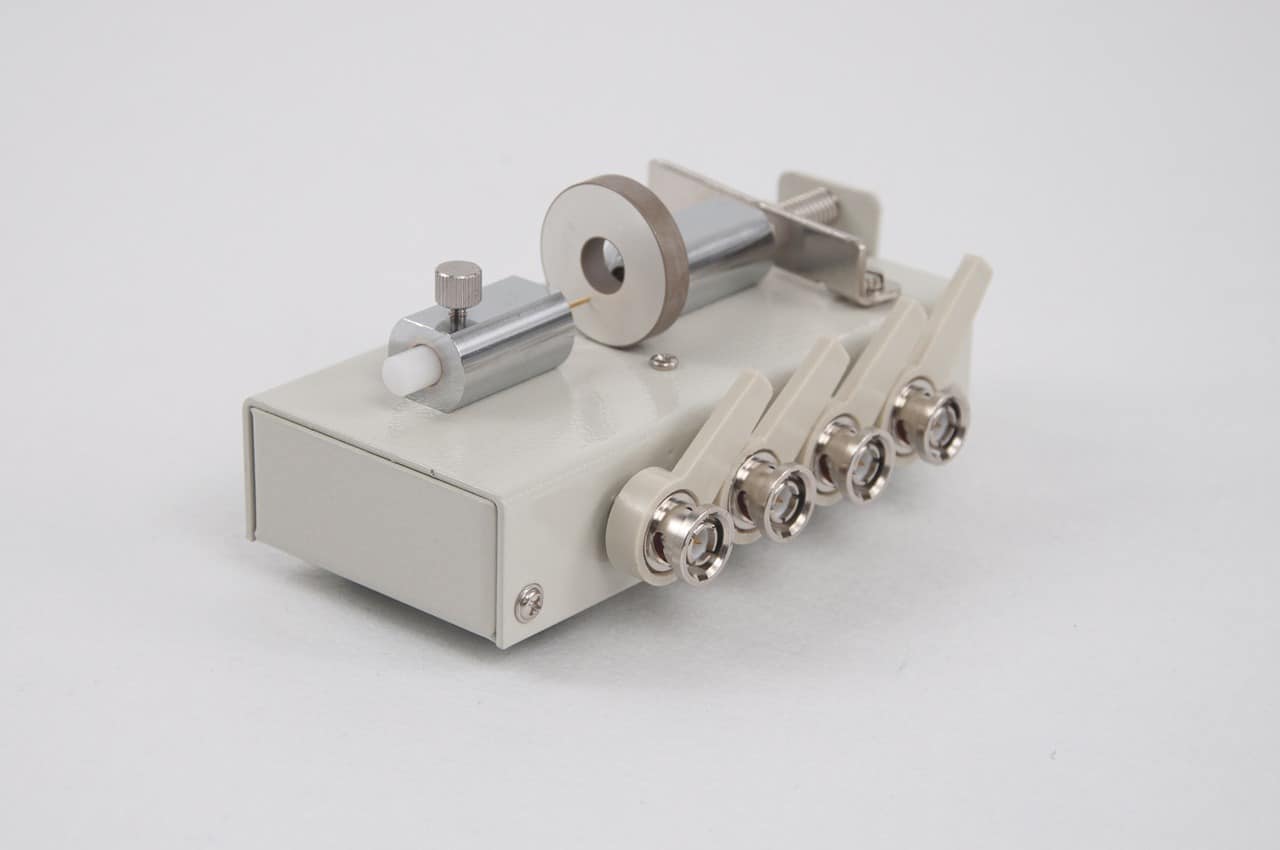

The core components of an ultrasonic cutter consist of a “transducer” responsible for generating ultrasonic oscillations and an “oscillator” that drives the transducer. The transducer incorporates piezoelectric elements, which, when subjected to an AC voltage at their characteristic frequency, induce mechanical vibrations. This resonance state causes the cutting blade to oscillate vigorously, allowing for precise and clean cuts.

Additionally, ultrasonic cutters often feature a feedback-control system that monitors and maintains the oscillation frequency and amplitude, ensuring consistent and sharp cutting even under varying loads. This precise control minimizes waste and contributes to a cleaner and more sustainable cutting process.

In conclusion, ultrasonic cutters are indispensable tools in modern materials processing, offering unparalleled precision, efficiency, and versatility across various industries. Their ability to cut, trim, and shape materials with minimal waste and maximum efficiency makes them an integral part of today’s manufacturing and processing workflows.

Where can I buy it? Click Here!!